| Sign In | Join Free | My carsrow.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My carsrow.com |

|

Brand Name : WL

Model Number : WL-Co21

Place of Origin : China

MOQ : 5KG

Payment Terms : L/C, T/T

Supply Ability : 300 tons per month

Delivery Time : within 10 days

Packaging Details : 5kg/bottles, 4 bottles/carton

Price : Negotiable

Shape : Powder

Color : Dark Gray

Chemical Composition : Co Cr W Fe C Ni Si

Sample : Available

Process : PTA, HVOF, Laser Cladding, Plasma Spray, Spray-Fuse

Application : Hardfacing & Wear-resistant Welding

Certificate : ISO9001

Hardness : 20-35 HRC

Test Report : Mill-Certificate

Free Documents : CO, Form A E F P, FTA

Label : Brand, Neutral Or Customized

Currency : USD/EUR/GBP/RMB

Stellite 21 Hardfacing Welding Thermal Spraying Powder Cobalt Alloy Powder

Product Description

WL Co-21 is recommended for applications involving cavitation, erosion, corrosion and/or high temperatures, such as valve trim for petrochemical and power generation. WLCo-21 has excellent resistance to thermal and mechanical shock. Optimum high temperature strength is obtained by solution heat treatments at 1200-1240ºC (2190 - 2265ºF) followed by quenching, and aging in the temperature range 700-1150°C (1290-2100°F). Due to its good impact resistance, it has been widely used in the building up of forging or hot stamping dies.

Common Names: Stellite 21 Polystel 21

Standard: AWS 5.21-2001 ERCoCr-E

CHEMICAL COMPOSITION(%)

| C | Si | Mn | Mo | Cr | W | Ni | Fe | Co |

| 0.25 | 1.50 | ≤0.50 | 5.50 | 27.30 | ≤0.50 | 2.00 | 1.50 | Rest |

Particle size (µm)

180/53, 180/63, 150/45, 150/63, 150/53, 125/38, 250/45, 45/20, 53/20

CHARACTERISITIC

| Abrasion Resistance | Moderate |

| Impact Resistance | Excellent |

| Corrosion Resistance | Good |

| Hardness | HRC 20-35 |

| Deposit Layers | Multiple |

| Deposit Cross Checks | No |

| Magnetic | No |

| Hot Wear Hardness | Good |

| Machineability | Carbide Tools |

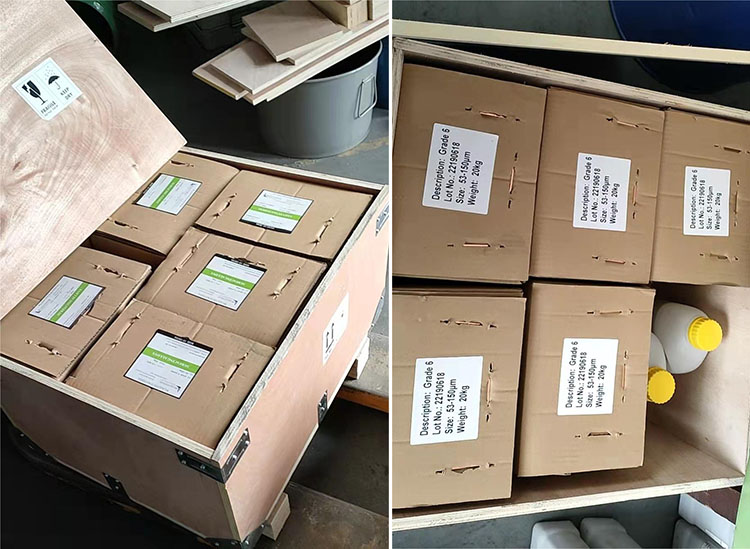

Packing Details

Each bottle 5kg/bottles, 5 bottles pack in one carton,

then put cartons onto pallet or Box. OEM packing & label or customized packing methods available.

APPLICATIONS

Type we could offer

| Trademark | Nominal Chemical Composition | HRC | Application | |||||||||

| C | Cr | Si | W | Ni | Fe | Mn | Mo | Co | B | |||

| WL Co1 | 2.45 | 30.0 | 1.0 | 13.0 | ≤3.0 | ≤3.0 | ≤1.0 | ≤1.0 | Bal. | 50-58 | Valve seat insets, bearing, sawteeth, rotary ring, Pump Sleeves | |

| WL Co3 | 2.4 | 30.5 | 1.0 | 13.0 | ≤3.0 | ≤3.0 | ≤1.0 | ≤1.0 | Bal. | 50-56 | Valve seat insets,steel mill guide roll, wearing panel of cracker blade, etc. | |

| WL Co4 | 1.0 | 31.0 | 1.0 | 14.0 | ≤3.0 | ≤1.0 | ≤0.5 | ≤0.5 | Bal. | 45-50 | Hot extrusion die, dry battery industry | |

| WL Co6 | 1.2 | 29.0 | 1.0 | 4.5 | ≤3.0 | ≤3.0 | ≤1.0 | ≤1.0 | Bal. | 40-46 | Engine valve, high temperature valve, turbine blade | |

| WL Co12 | 1.4 | 30.0 | 1.3 | 8.5 | ≤3.0 | ≤3.0 | ≤1.0 | ≤1.0 | Bal. | 44-50 | Pressure valves, sawteeth screw fights | |

| WL Co20 | 2.5 | 32.0 | 1.0 | 17.0 | ≤3.0 | ≤3.0 | ≤0.5 | ≤1.0 | Bal. | 54-59 | Wear plate, bearing sleeve, etc. | |

| WL Co21 | 0.2 | 27.0 | 1.0 | 0.2 | ≤3.0 | ≤2 | ≤1.0 | ≤5.5 | Bal. | 20-40 | Fluid valve seat, turbine blades, hot forging die | |

| WL Co25 | 0.05 | 20.0 | 1.0 | 15.0 | 10.0 | ≤2.0 | ≤1.5 | ≤1.0 | Bal. | 24 | High temperature and corrosion-resistant valve sealing surface, pressure casting dies, etc. | |

| WL Co31 | 0.5 | 26.0 | 1.0 | 7.5 | 10.0 | ≤3.0 | ≤1.0 | ≤1.0 | Bal. | 30-35 | Extrusion die, steam turbine blade, etc. | |

| WL Co32 | 1.8 | 26.0 | 1.2 | 12.0 | 22.0 | ≤1.5 | ≤0.5 | ≤1.0 | Bal. | 40-45 | Engine inlet and exhaust valve | |

| WL Co190 | 3.2 | 26.0 | 1.0 | 14.0 | ≤1.0 | ≤3.0 | ≤1.0 | ≤1.0 | Bal. | 54-60 | Petroleum drill bit, mining industry | |

| WL CoT400 | 0.08 | 8.5 | 2.6 | 1.5 | ≤1.5 | ≤1.0 | 28 | Bal. | 0.8 | 50-60 | Valve and roller path, plastic extruder in strongly corrosive | |

| WL CoT800 | 0.08 | 18.0 | 3.4 | ≤1.5 | 1.5 | ≤1.0 | 28 | Bal. | 0.8 | 52-58 | Valve and roller path, plastic extruder in strongly corrosive | |

|

|

Stellite 21 Hard Facing Powder Welding Cobalt Alloy Thermal Spraying Powder Images |